Hydro Clean

Let’s take care of your heating circuits and your home

Since the beginning of the 1970s, in most new buildings in Switzerland, building professionals have installed underfloor heating. Plastic pipes were generally used. These are exposed to embrittlement and siltation and can cause problems after just 10 years.

The problems are mainly related to first generation single-layer plastic pipes. Crossing the layer, oxygen molecules diffuse inside the pipe and attack metal components such as taps and other boilers. The residues of this corrosion then lead to a solid accumulation of sludge throughout the circuit. The pipes are also constantly exposed to thermal variations, thus accelerating the evaporation of the stabilizers contained in the plastic.

Result: the weakening of the material, a process which initially goes unnoticed. Over time, this weakening causes cracks in the pipe material. These cracks manifest themselves in the form of pressure loss and the reduction in thermal power is compensated by an increase in starting temperatures. Consumption of fossil fuels, such as fuel oil or gas, as well as electricity in the case of heat pumps, is stopping increasing. Not to mention the repair costs which will be added following the various leaks. Water damage is then to be feared.

Our HydroClean uses cutting-edge technology to rid your pipes of unwanted deposits, but without using electricity and harsh chemicals. It is a revolution in the field of piping, combining efficiency and respect for nature.

Made with premium materials, our HydroClean is built to last, reducing the need for replacement and maintenance.

Make an informed choice for your home, for the planet, and for future generations. Opt for High-End Ecological HydroClean and be part of the solution.

Installation

- Install the system after the circulator (boiler outlet)

- Install on a straight portion respecting the minimum distance

- Horizontal or vertical installation

- Install a 2nd system after the circulator (if there is a plate exchanger)

- Move the system away from magnetic fields

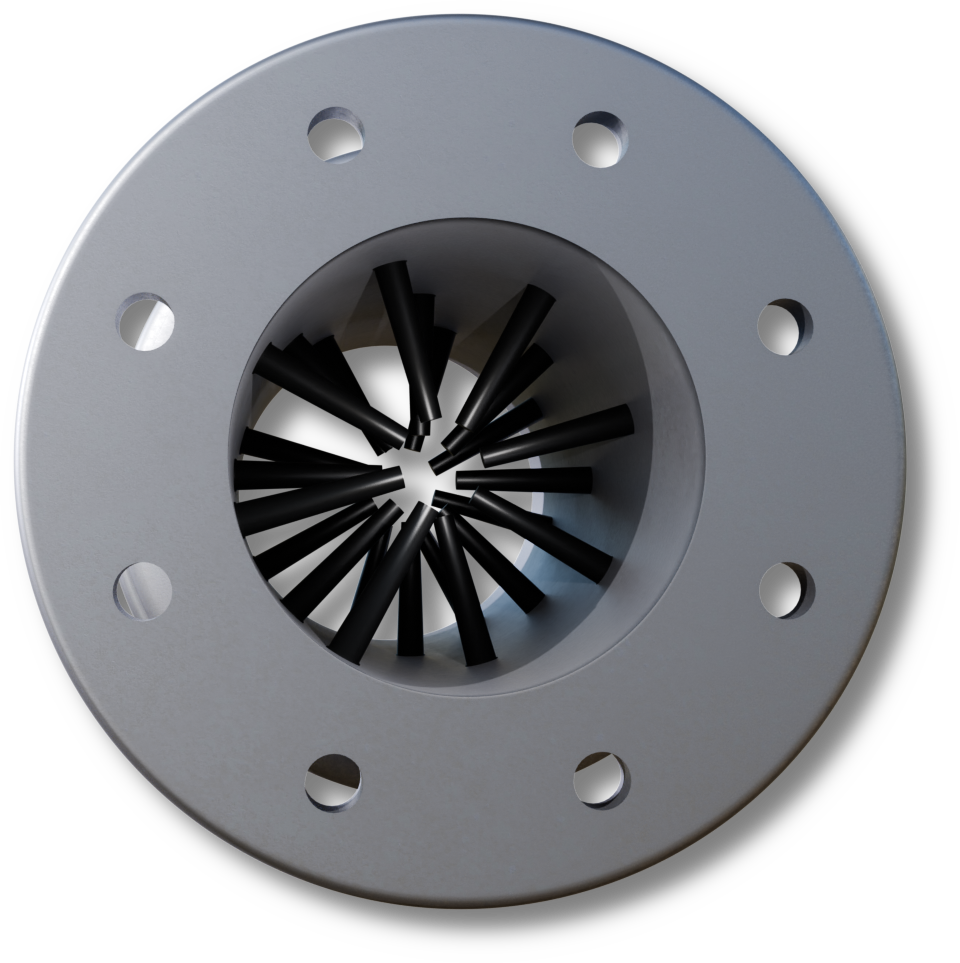

Principle of operation

No hydraulic impact, low pressure loss of 0.25 bar at outlet.

Significant reduction in ferrous materials by redox, with stabilization of PH and conductivity.

Autonomous, curative and preventive action to facilitate maintenance.

Neutralization of bacteria and corrosion.

Extended lifespan of boilers, exchangers, boilers, and buffer tanks. As well as underfloor heating and cooling circuits.

Results

Disappearance of sludge

Improvements in efficiency and heat exchange

Savings on energy costs

Removal of chemicals

Significant reduction in maintenance and operating costs

Extended lifespan of installations

Ease of installation and implementation

Corrosion is a disturbance created by the imbalance between these three elements: water, oxygen, materials. The latter manifests itself by the creation of mud due to corrosive water, the water becomes foggy.

Thanks to the Vortex phenomenon, the water is instantly regenerated as it passes through the Hydro Clean which will disintegrate any type of sludge (bacterial, algae or metallic) and prevent scaling of the network.

Benefits

Compared to the classic method

Final solution

Without chemicals

Environmentally friendly

Avoided overconsumption

Reduction in energy bill

Hydraulic breakdowns avoided

Guaranteed operation of heat generating equipment

Reduction in bacterial proliferation

Reduced risk of leakage